Towards inkjet printable conducting polymer artificial muscles

Inkjet printing is a key technology in the field of defined polymer deposition as well as in fabrication of strain sensors. It is also one of the most promising alternatives to prevalent fabrication of conducting polymer actuators. Nevertheless, inkjet printed actuators were not yet realised due to rheological properties of conducting polymer solutions that challenge jetting and the complex solution–membrane interactions, that lead to poor adhesion or uncontrolled infiltration. In order to enable this fabrication method, hybrid hydrophilic-hydrophobic polyvinylidene fluoride (PVDF) ultrafiltration membranes were used. They ensure good adhesion with printed poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) layer. Furthermore, PEDOT:PSS compositions that have liquid properties suitable for printing but do not cause uncontrolled infiltration through the membrane were identified. This allowed the realisation of the first inkjet printed PEDOT:PSS based ionic actuators working in air.

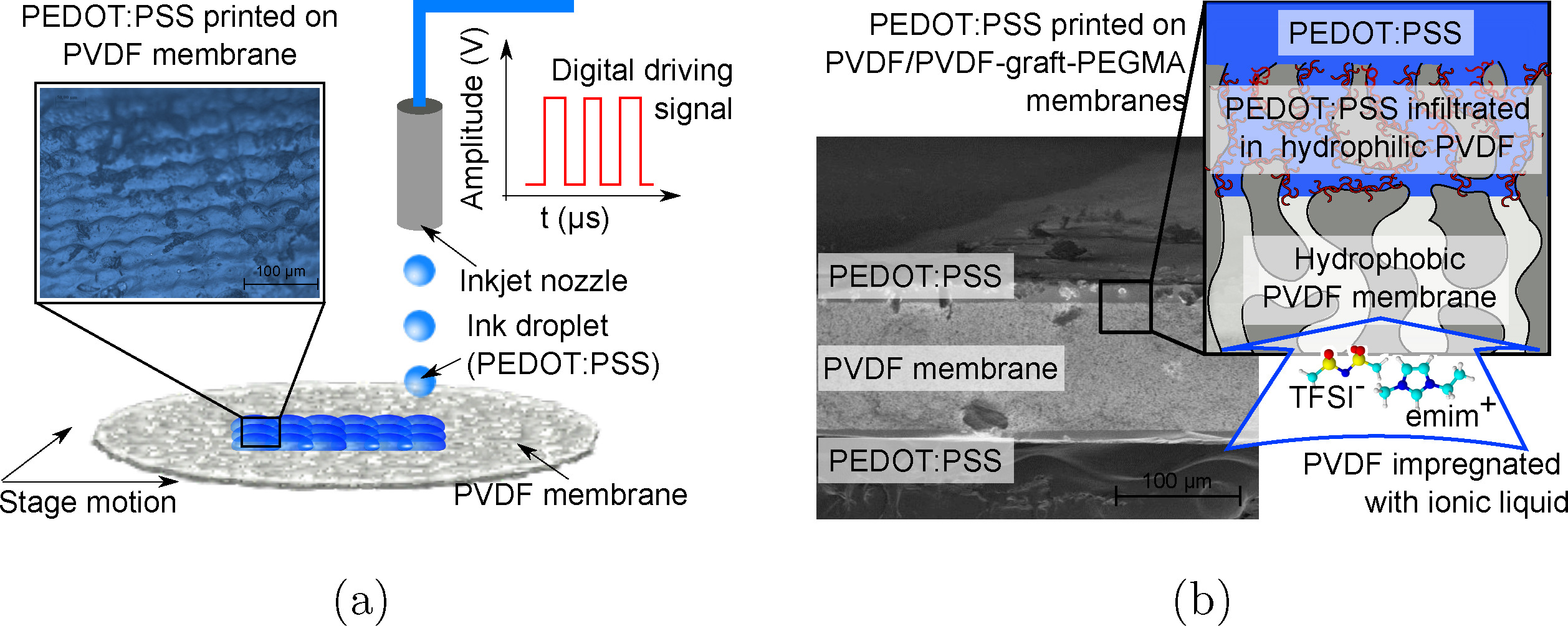

Schematic illustration of a piezoelectric drop-on-demand (DoD) inkjet printing: a voltage wave is used to deform piezoelectric material and generate a pressure pulse in the fluid, which subsequently ejects a droplet of ink (PEDOT:PSS) from the nozzle; a pattern is generated by moving the stage with the substrate (PVDF membrane) in two dimensions. Inset: Picture taken with optical microscope after 20 layers of PEDOT:PSS were printed. (b) SEM image of the cross-section of the inkjet printed actuator and schematic illustration of its structure.