Thermoelectric Higher Manganese Silicide

Complex geometry legs were advantageous to obtain higher thermoelectric potential due to a better thermal dissipation. Among all industrial processes, additive manufacturing using a selective laser sintering (SLS) or melting (SLM) techniques is the most promising to obtain such complex-shape legs without machining step. In this work, for the first time, Higher Manganese Silicide (HMS) sheet samples were synthetized, sintered and shaped simultaneously by additive manufacturing from ball milled manganese and silicon powder. Impact of surface power density and scanning rate of the laser on the microstructural and structural properties was discussed for some SLS/M parameters. Characterizations have shown that both densification and pure HMS phase can be obtained by SLS/M.

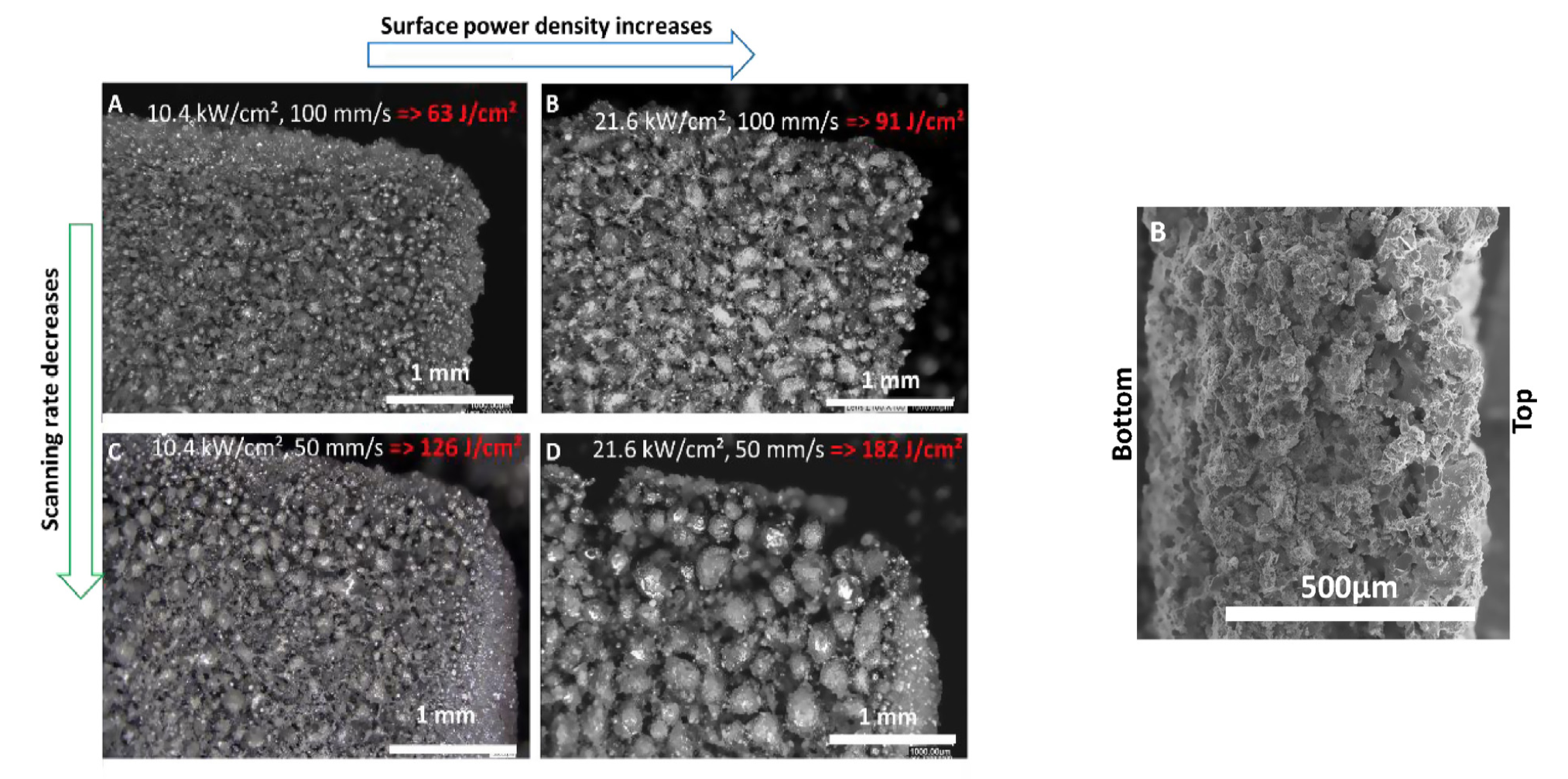

(Left) optical micrographies of the surface of the sheet samples made under various SLS/M energy doses (J/cm2), Surface Power Density (kW/cm2), laser scanning rates (mm/s). (Right), a cross section of the sample B.

More informations: Thermoelectric Higher Manganese Silicide: Synthetized, sintered and shaped simultaneously by selective laser sintering/Melting additive manufacturing technique. Yohann Thimont, Lionel Presmanes, Vincent Baylac, Philippe Tailhades, David Berthebaud, Franck Gascoin. Materials Letters (2018) 236–239