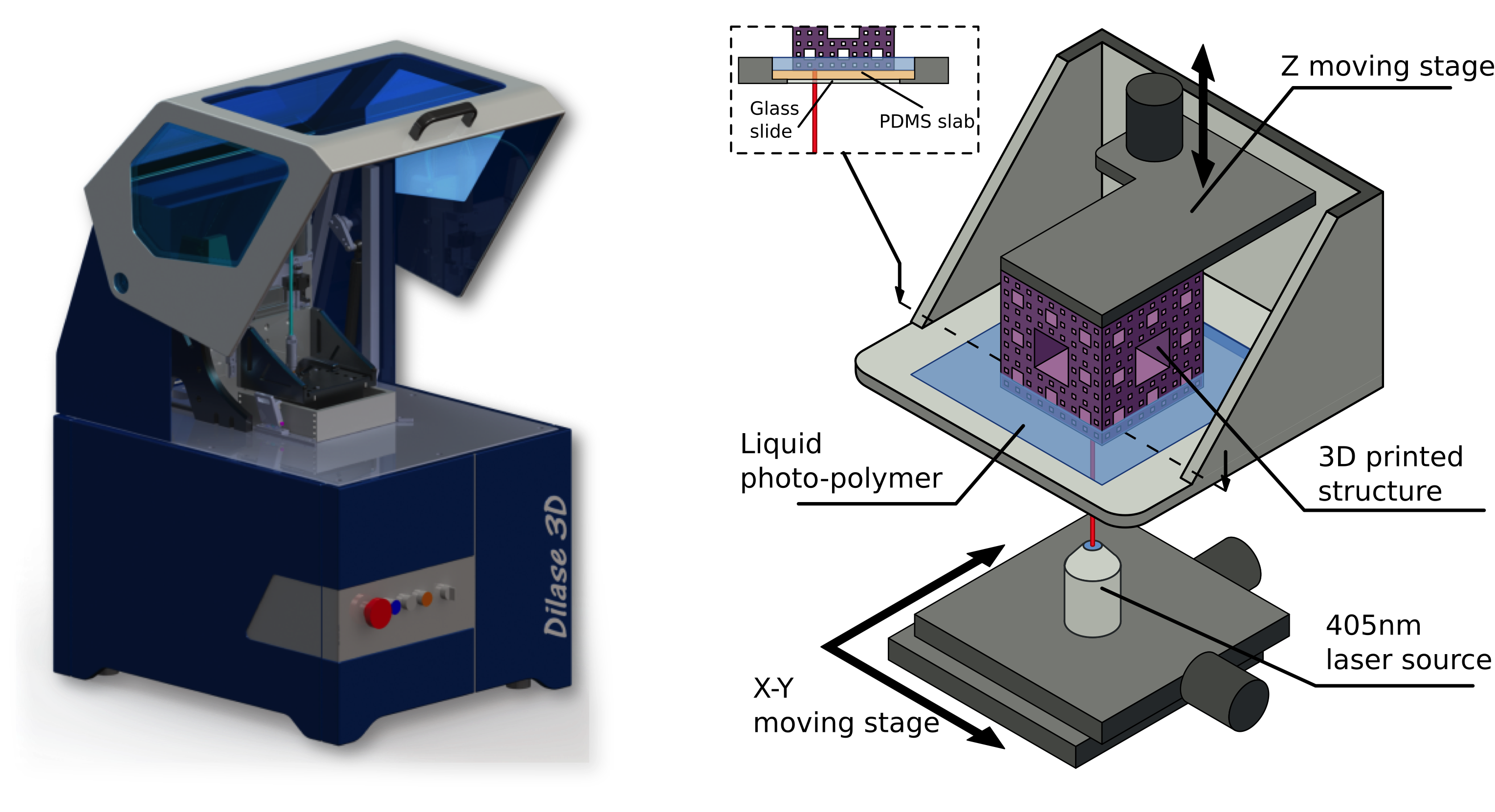

Dilase 3D HR : High Resolution Stereolithography

Stereolithography is an additive manufacturing process based on the polymerization of liquid photocurable materials. Kloé and LAAS have established a collaboration for the development of equipments and processes devoted to high resolution 3D printing. Based on their long experience in laser photolithography and material processing, the partners have developed high-resolution 3D printing tool (DILASE 3D, Kloe) providing an unprecedented resolution of 5µm (X,Y,Z). Dilase 3D enables the fabrication of high resolution microsystems with a total printing volume of 100 x 100 x 50mm³.

Technical specifications :

- Object size : 10 cm x10 cm x 5 cm

- Targeted Resolution X,Y : 5um

- Targeted Resolution Z : 5-100um (adjustable)

- Laser Wavelength : 405 nm (50 mW)

- Writing speed : 100mm/s

- Alignment module

- Stereolithography

Applications :

- Direct laser fabrication of meso-scale 2D and 3D architectures with micrometric feature resolution

- DLD: hydrodynamic microfluidic device

- Fabrication of 3D scaffolds reproducing intestinal epithelium topography by high-resolution 3D stereolithography