Direct laser fabrication of meso-scale 2D and 3D architectures with micrometric feature resolution

The realization of 2D and 3D meso-scale architectures is an area of research involving a wide range of disciplines ranging from materials science, microelectronics, phononics, microfluidics to biomedicine requiring millimeter to centimeter-sized objects embedding micrometric features. In the recent years, several technologies have been employed to provide optimal features in terms of object size flexibility, printing resolution, large materials library and fabrication speed. In this work, we report a fully customizable single-photon absorption 3D fabrication methodology based on direct laser fabrication (Dilase 3D). To validate this approach and highlight the versatility of the setup, we have fabricated a comprehensive ensemble of 2D and 3D designs with potential applications in biomimetics, 3D scaffolding and microfluidics. The high degree of tunability of the reported fabrication system allows tailoring the laser power, slicing and fabrication speed for each single area of the design. These unique features enable a rapid prototyping of millimeter to centimeter-sized objects involving 3D architectures with true freestanding subunits and micrometric feature reproducibility. The presented strategy fills indeed the current technological gap related to the development of meso-scale architectures required in multidisciplinary fields of research.

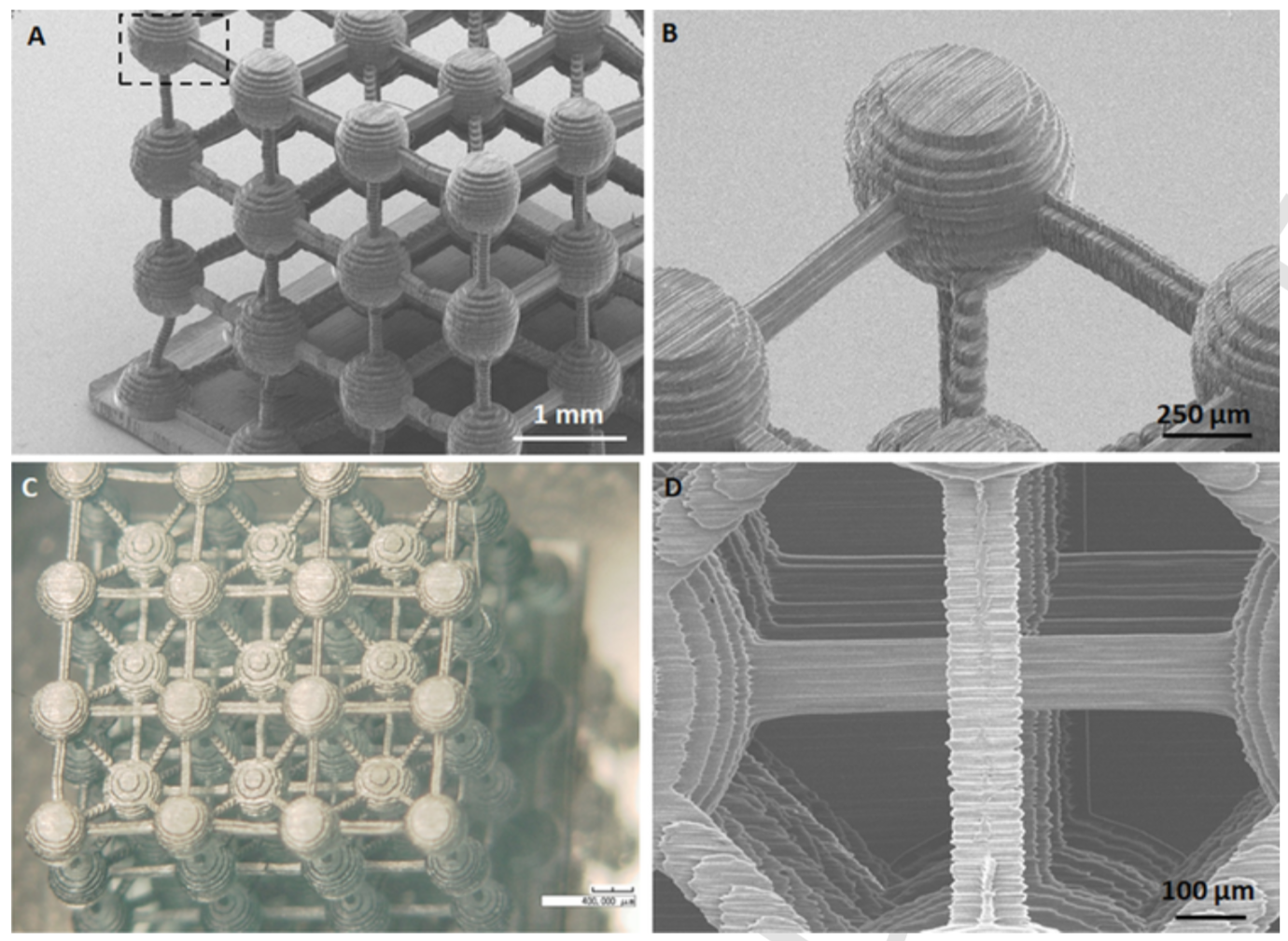

Left : A: SEM micrograph of the atomic structure design; B: SEM micrograph close-up on a unit block (framed region in A) of the atomic structure; C: Optical micrograph of the atomic structure; D: SEM micrograph close-up on the cylinders interconnecting the spherical units.

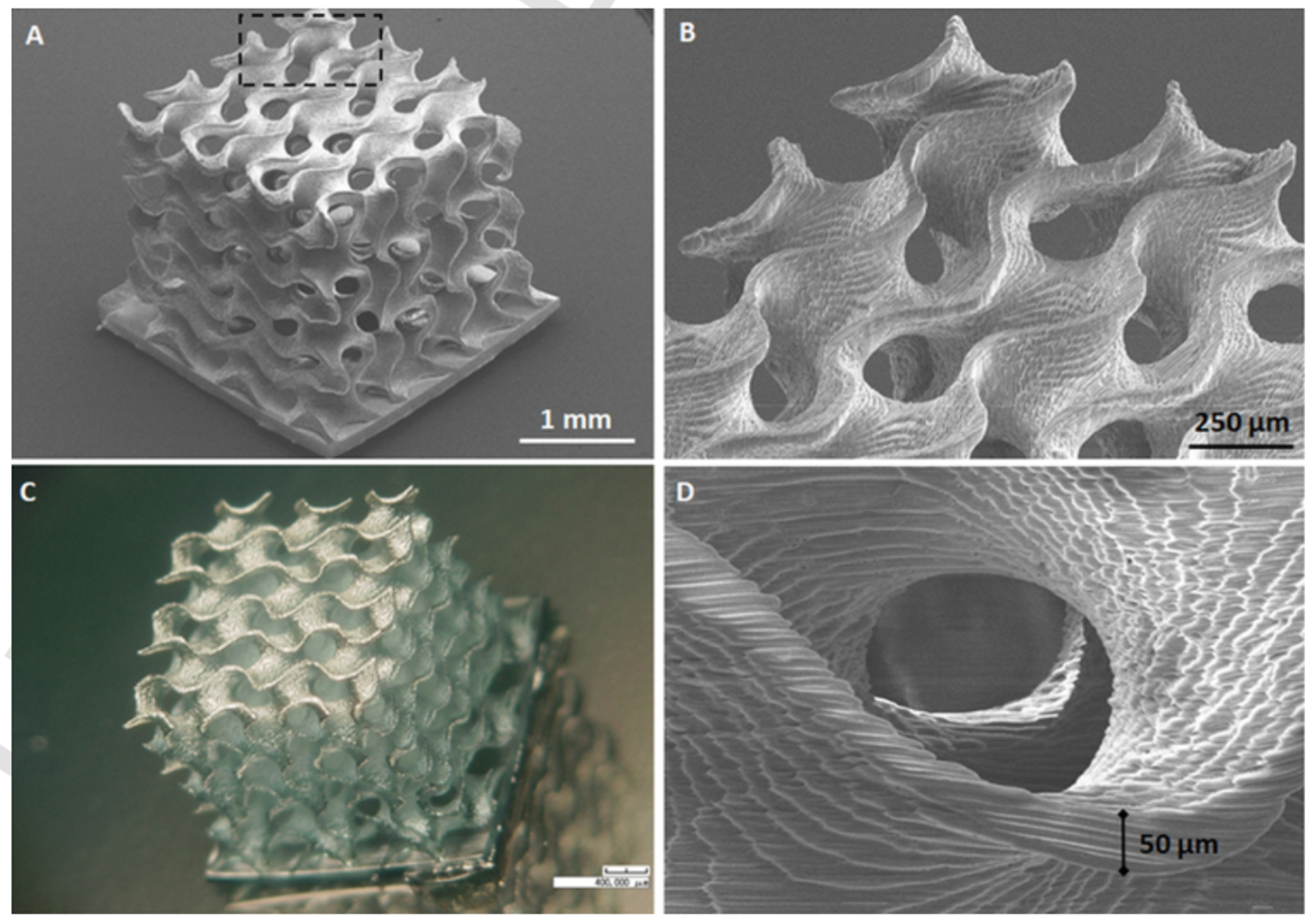

Right : A: SEM micrograph of the whole gyroid design; B: SEM micrograph close-up on the periodic features (framed region in A) of the gyroid; C: Optical micrograph of the gyroid archi- tecture; D: SEM close-up of the apertures of the gyroid architecture.